dry polyacrylamide

Links

-

CSPI’s Chemical Cuisine is the web’s definitive rating of the chemicals used to preserve foods and affect their taste, texture, or appearance. Besides titanium dioxide, the group recommends avoiding artificial sweeteners like aspartame, acesulfame potassium, and sucralose, as well as synthetic food dyes like Yellow 5 and Red 3. CSPI and others have recently asked the Food and Drug Administration to ban the latter dye in foods and ingested drugs because the FDA has already determined that it is a carcinogen unsafe for use in cosmetics.

-

- The profiles of key players and their key strategic developments are enlisted in the report.

- On the technological frontier, titanium dioxide’s ability to interact with light has seen it being explored for use in solar cells and sensors. Nanotechnology is pushing the boundaries of what was once considered just a pigment, suggesting that TiO2 could hold the key to more efficient energy conversion processes in the future.

-

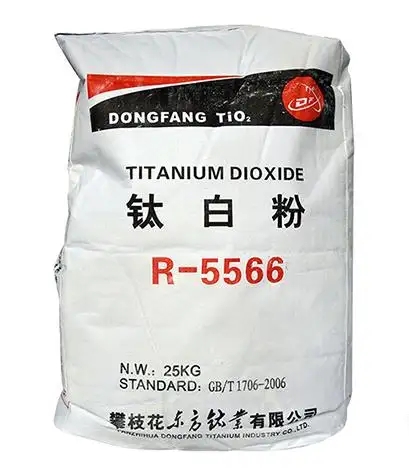

It is an anatase titanium dioxide pigment produced by a special process from sulfuric acid. Widely used in PVC pipes, interior coatings, industrial pigments, rubber, leather, polyolefins, Printing ink, plastic, paper, etc.

Health Canada's Food Directorate recently completed a “state of the science” report on titanium dioxide (TiO2) as a food additive. Food-grade TiO2 is a white powder made up of small particles that has been permitted in Canada and internationally for many years as a food additive to whiten or brighten foods. Food-grade TiO2 has long been considered safe in Canada and in other countries when eaten as part of the diet.

2. Mentality: the buyer has to prepare goods in advance, and the new order price is slightly less willing to purchase in bulk;

Recent analyses of food-grade TiO2 samples have found that a significant portion of particles may be within the nanoscale. These particles (also known as nanoparticles) range in size from 1 to 100 nm, where 1 nm equals 1 billionth of a metre (the width of a typical human hair is 80,000 to 100,000 nm).

It is added to these materials to improve their strength, durability, and resistance to UV radiation It is added to these materials to improve their strength, durability, and resistance to UV radiation

It is added to these materials to improve their strength, durability, and resistance to UV radiation It is added to these materials to improve their strength, durability, and resistance to UV radiation titanium dioxide powder uses suppliers. Reliable suppliers of titanium dioxide powder play a key role in helping manufacturers of plastic and rubber products meet the performance and quality standards demanded by customers.

titanium dioxide powder uses suppliers. Reliable suppliers of titanium dioxide powder play a key role in helping manufacturers of plastic and rubber products meet the performance and quality standards demanded by customers. Thanks to its rheological and optical properties, Lithopone offers both technical and economic advantages wherever organic and inorganic binder systems require a relatively high pigmentation for specific applications.

Various titanium-rich minerals, including ilmenite and rutile, can serve as starting materials for the production of highly purified Titanium Dioxide. The predominant method employed in Titanium Dioxide production is the chloride process. In this process, the mineral, along with coke and chlorine, undergoes a reaction within a fluidized bed, resulting in the formation of primarily titanium tetrachloride and carbon dioxide. Subsequently, the titanium tetrachloride undergoes purification and conversion to Titanium Dioxide. Another method involves treating ilmenite with sulfuric acid to manufacture the chemical.

≥ 5 % of standard sample

As consumers become more conscious about their health and the environment, manufacturers are increasingly turning to titanium dioxide as a safe and effective alternative to harmful chemicals As consumers become more conscious about their health and the environment, manufacturers are increasingly turning to titanium dioxide as a safe and effective alternative to harmful chemicals

As consumers become more conscious about their health and the environment, manufacturers are increasingly turning to titanium dioxide as a safe and effective alternative to harmful chemicals As consumers become more conscious about their health and the environment, manufacturers are increasingly turning to titanium dioxide as a safe and effective alternative to harmful chemicals wholesale e 171 titanium dioxide.

wholesale e 171 titanium dioxide.  The titanium dioxide helps to protect the Ponceau 4R from external factors such as heat and light, while also providing a white base that gives the colorant a more vibrant and appealing appearance The titanium dioxide helps to protect the Ponceau 4R from external factors such as heat and light, while also providing a white base that gives the colorant a more vibrant and appealing appearance

The titanium dioxide helps to protect the Ponceau 4R from external factors such as heat and light, while also providing a white base that gives the colorant a more vibrant and appealing appearance The titanium dioxide helps to protect the Ponceau 4R from external factors such as heat and light, while also providing a white base that gives the colorant a more vibrant and appealing appearance ponceau 4r and titanium dioxide manufacturer.

ponceau 4r and titanium dioxide manufacturer. This route affords a product that is 29.4 wt % ZnS and 70.6 wt % BaSO4. Variations exist, for example, more ZnS-rich materials are produced when zinc chloride is added to the mixture of zinc sulfate and barium sulfide.[1]

4. Paper and Textiles

They should have a robust supply chain, ensuring timely deliveries, and possess a deep understanding of the product's applications and requirements They should have a robust supply chain, ensuring timely deliveries, and possess a deep understanding of the product's applications and requirements

They should have a robust supply chain, ensuring timely deliveries, and possess a deep understanding of the product's applications and requirements They should have a robust supply chain, ensuring timely deliveries, and possess a deep understanding of the product's applications and requirements titanium iv oxide rutile supplier.

titanium iv oxide rutile supplier.  silver titanium dioxide supplier. They strive to provide timely delivery, even across long distances, to ensure that their customers' production schedules are not interrupted due to supply shortages.

silver titanium dioxide supplier. They strive to provide timely delivery, even across long distances, to ensure that their customers' production schedules are not interrupted due to supply shortages.